- Materials and Chemistry Laboratory

The following services are provided by the metallurgical and chemical laboratory of the Charkheshgar Company:

- Measuring surface hardness of parts (HRC, HV, HRB, HB, …)

- Measuring the penetration depth of hardness of parts (carburizing, nitriding, carbonitriding)

- Measuring the core hardness of parts (without destruction and with destruction of parts)

- Preparation of graphs and charts of hardness in different depths of parts

- Determining the type of heat treatment performed on the parts

- Preparing the metallographic structure of ferrous and non-ferrous parts

- Determining the percentage of metallurgical phases

- Determining the type of graphite and the degree of sphericity (Nodule Count) of cast iron parts

- Magnetic crack test of parts

- Measuring the ph of coolant liquid

- Measuring the viscosity of oils

- Salt spray test

It must be mentioned that in addition to the above measurement services, checking and providing analysis of control cases as well as consulting services are performed by the experts and specialists of the laboratory of the company.

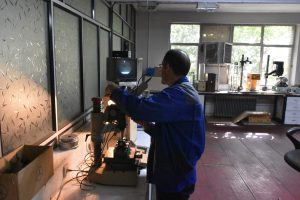

- Metrology Room

Providing all kinds of accurate measurement services by the metrology department of the company, as follows:

- Providing graphs of different points of machined parts, gears, shafts, etc. in different magnifications

- Measuring the geometric characteristics of complex parts using precise measuring equipments including items such as: roundness, cylindricalness, sphericity, orthogonality, etc.

- Measuring the quality and roughness of surfaces and preparing their graphs

- Accurate dimensional measurements of gear parts and grooved shafts

- Controlling and reporting the quantitative and qualitative results of parts using the available advanced and precise equipments for reverse engineering in the implementation of new projects.