Undoubtedly, growth and development are one of the most basic needs of organizations to achieve excellence. What is proposed as the main competitive advantage in organizations with economic goals is development at a pace that is appropriate and in line with the surrounding world. In other words, competition is the main motivation for the growth and development of companies. Research, on the other hand, is the catalyst of success in all organizations and the difference is only in its goal and achievements.

A research and development department has been established in the Charkheshgar company, for the purpose of designing and developing new products, as well as reverse engineering and localization of the required products. By forming specialized working teams in the required fields, the company is engaged in carrying out relevant activities. Team work with expert leading is one of the main strategies of this unit, which is always considered in all activities, and the success of this department is due to the continuous efforts of all its employees.

The activities carried out in R&D department include various sections that can be generally presented under the following items:

1. Product design:

a) Designing the general platform of the gearbox Concept design:

According to the planned need, based on the technical knowledge and experience gained from years of research and examination of various types of common gearbox systems, the stages of designing the general platform of the gearbox are carried out, which includes the following two parts:

- Compilation of a comprehensive constitution of gearbox design

- Preparation of standards and resources

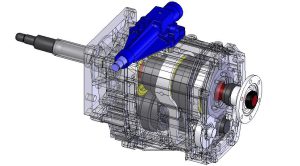

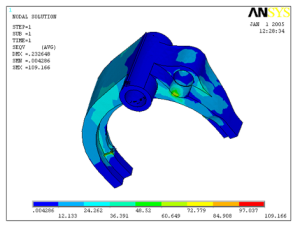

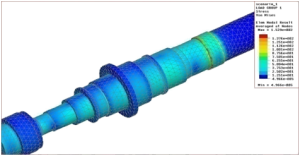

b) Design and analysis of the internal components of the gearbox:

Using expert personnel and taking advantage of world-class knowledge, along with making use of gear and gearbox design and finite element analysis software, different internal parts of the gearbox considering their designs and assemblies were evaluated in diverse working conditions. This section includes several steps, some of which are mentioned below:

- Design and optimization of shafts and bearings

- Design of synchronizer assemblies

- Design and analysis of gearbox casing

- Designing the mechanism of shifting forks

- Analysis of lubrication and ventilation in gearbox

- Analysis of stress, strain, fracture and failure of the internal parts of the gearbox

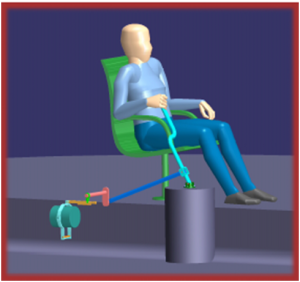

c. Research and design of various types of shifting mechanism systems:

Modifying the speed and torque in the gearbox according to the speed and torque input from the vehicle engine is carried out using the gear changing mechanism. This includes different types and can be designed and utilized based on gearbox types, type of vehicles and constraints of installation of the parts in the assembly complex. One of the activities of the research and development department is to determine the type of mechanism needed to implement the gear change and its design.

- Compilation of design knowledge of various mechanisms (Servo Shift-Cable-Linkage)

- Analysis of gear shifting mechanism forces in various gearboxes

2. Developing various production software:

With the help of top experts in the research and development department, the knowledge-based essentials of software within the unit have been examined and evaluated, and according to the defined needs, the required software, are designed and used. Among the activities carried out in this field, we can refer to the items mentioned below.

a. Compilation of the software for selecting and adapting all types of gearboxes to the vehicle

b. Development of gear profile control software (K-chart…)

c. Compilation of software for extracting gear shifting diagram